How a HEAD tennis racquet is made

Inside the HEAD tennis racquet factory with Ralf Schwenger, the director of research and development for Racquetsports.

Have you ever thought about how your favorite HEAD racquet is made? Ever considered all the materials, innovations and expertise that go into creating the frame that allows you to serve aces, rip winners and have fun on court? Wonder no more, as Ralf Schwenger, the director of research and development for Racquetsports, has shared some insights into what happens inside the HEAD factory in Kennelbach in Austria. How HEAD’s team of experts go about producing, as Schwenger put it, “the best racquet for you out there, the consumer”.

What are tennis racquets made from? And why do the materials need to be kept in a cold storage room?

Perhaps you’re already aware that tennis racquets are mostly made from graphite. What you might not know is that they are produced using graphite fibers that have been pre-impregnated with resin to create a material that is known as pre-preg.

To avoid the resin from hardening before it’s used to make a racquet, the pre-preg is kept in a cold storage room. “As with a lot of materials, it’s important to store them in a cool place. And, like with cooking, it’s important to only use the best ingredients,” said Schwenger.

The first step of the process is to cut the pre-preg – which comes in large sheets – into specific shapes that are then put together to form what Schwenger called “a kind of carpet”. Changing the direction of the graphite fibers alters the playability of a racquet – according to Schwenger, there are more than 420 billion combinations of pieces for making a tennis racquet. “At the pre-forming stage, the pre-preg is cut according to specific dimensions.

The different pieces are then put together and here it helps that the pre-preg pieces are very sticky,” Schwenger disclosed. “On the other hand, there is also a danger because if you stick them together in the wrong direction, you get a problem.

How do HEAD make racquets lighter?

HEAD has come a long way since the days when tennis racquets used to be made from wood; frames are created using advanced, space-age materials that deliver exceptional performance. As well as being lightweight, the materials that go into a modern HEAD racquet are also extremely strong and durable and allow players to generate high levels of power and spin.

What do the HEAD experts do with the pre-preg pieces?

Using a machine, that “carpet” of pre-preg pieces is rolled into a tube. As Schwenger explained, that tube will be “the base for the racquet frame”. This is highly skilled work – the team have deep experience of producing racquets to a high level of precision. This factory offers a unique blend of heritage and innovation – this is where HEAD’s iconic frames were made and also where prototypes are created of future, game-changing racquets.

How do you avoid wrinkles in a HEAD tennis racquet?

The team take great care when placing the material in the mold – and when adding any extra pieces for reinforcement in parts of the frame – as otherwise you will end up with wrinkles.

How long is that tube placed in the hot mold for?

‘Curing’ a HEAD tennis racquet in a hot mold takes around 10 minutes. “Pressurized air is added to the bladder [a bag] which is inside the tube and thereby expands and [shapes] all the pre-preg fibers to the mold. The mold is heated to about 150 or 160 degrees and it takes about 10 minutes until the racquet is cured and then we have our tennis frame,” said Schwenger. The racquet is hot when it comes out of the mold and needs to be handled with gloves.

Does the frame need to be cleaned up?

When the frame is in the hot mold, some of the resin in the pre-preg flows out. That excess resin must be removed, and the racquet sanded down, to produce the smooth, clean finish that a tennis player expects. “We trim off the excess resin,” said Schwenger. “And then we go on to a special surface treatment with vibrating stones.”

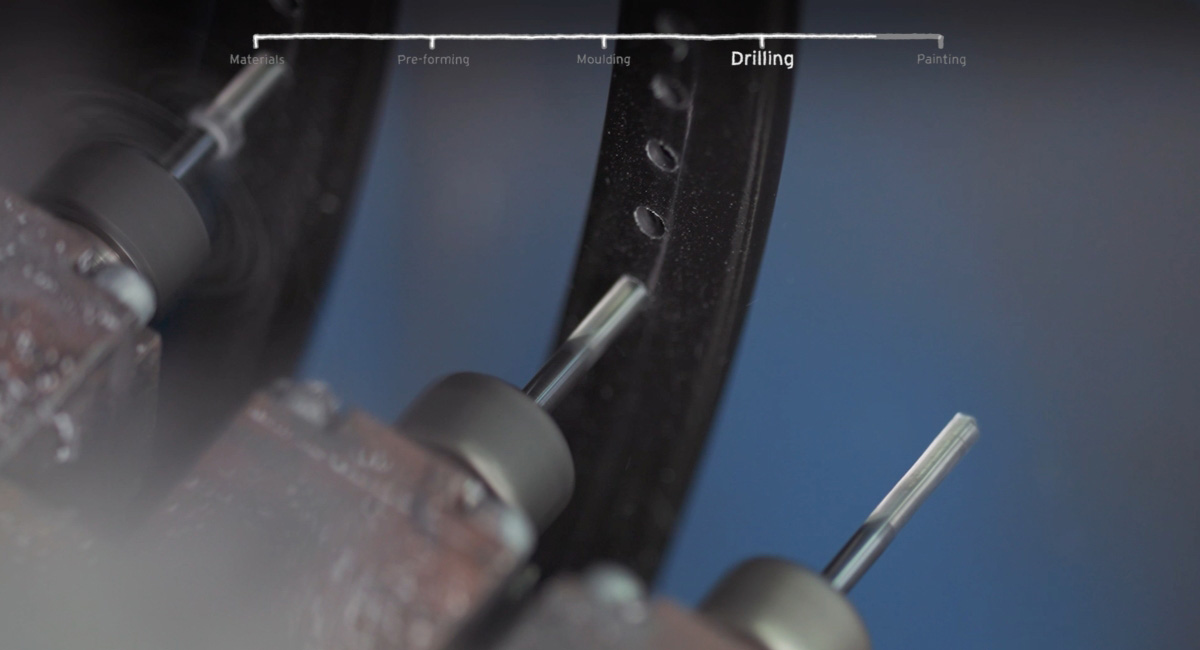

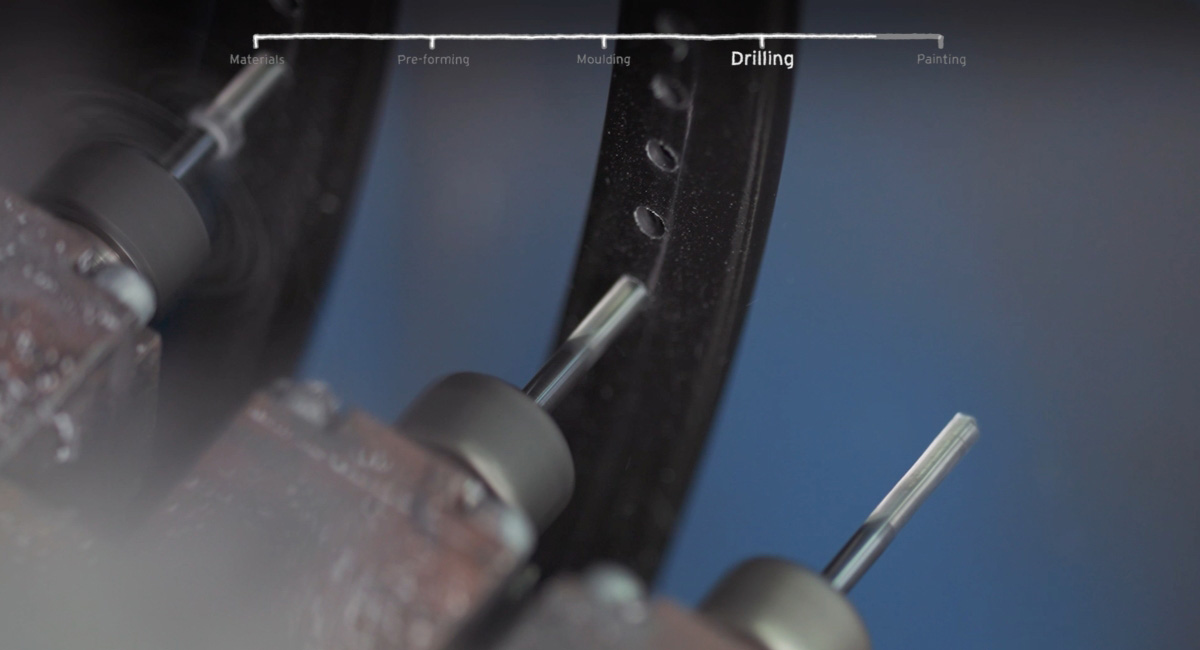

How is the racquet prepared for being strung?

The racquet is placed in a drilling machine which puts holes in the frame for the grommets. The positioning of the holes will depend on the string pattern. Once the grommets have been applied, the grip or handle will be finished with grip pallets, the butt cap and a base grip.

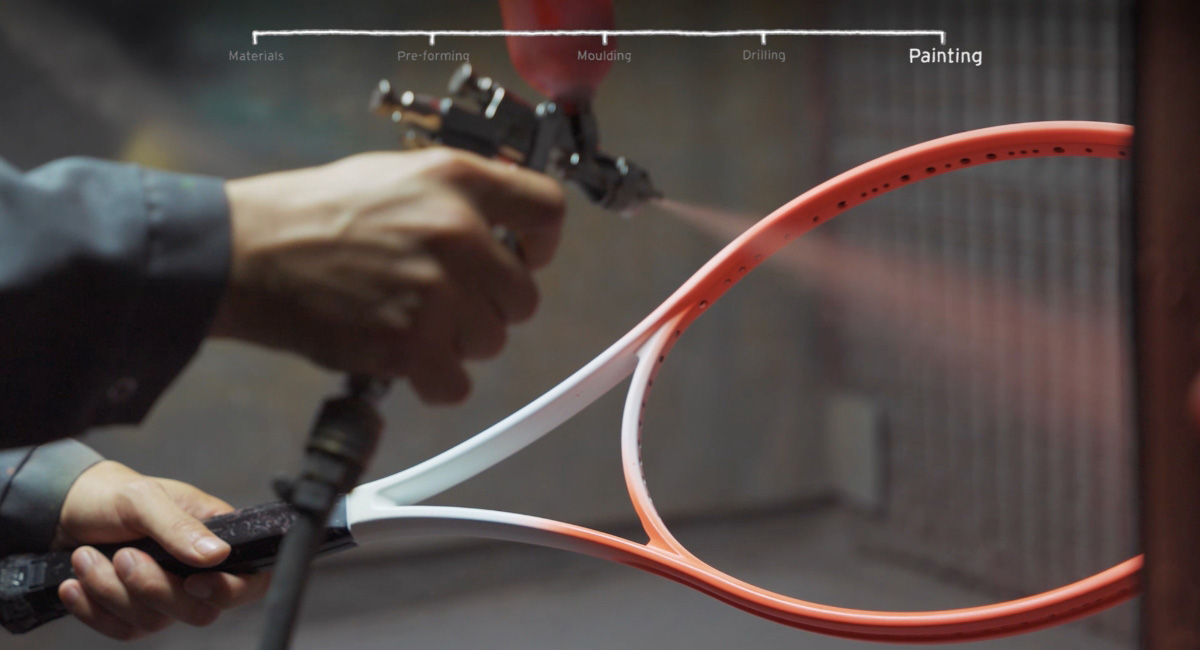

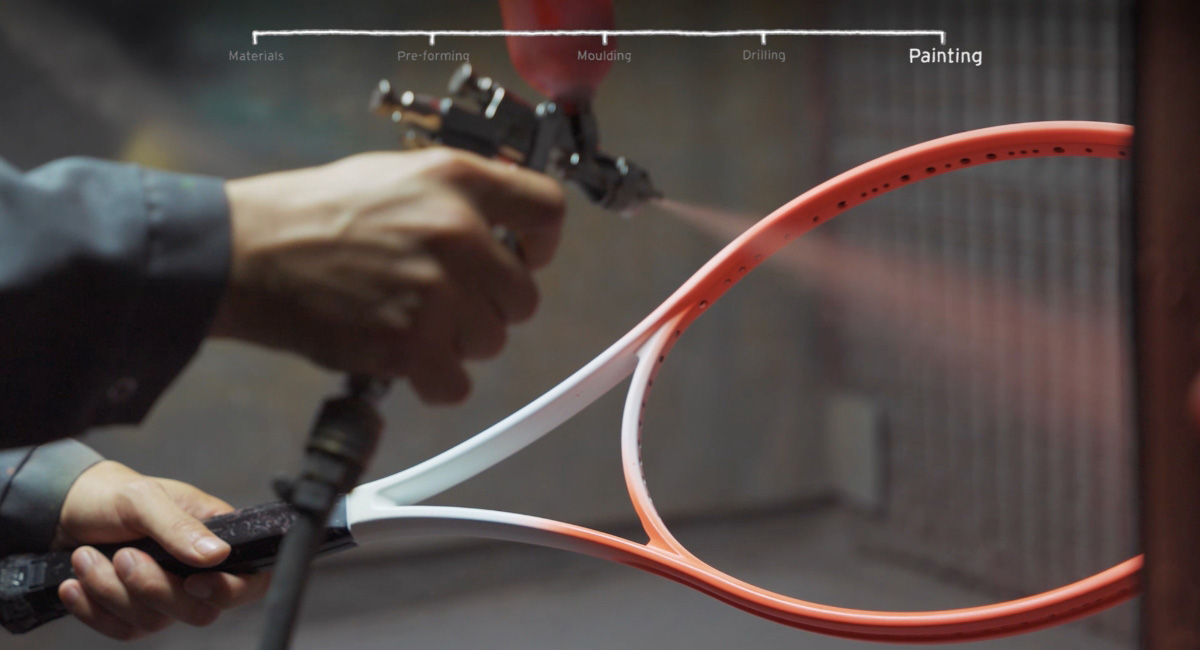

What’s the final part of the process?

“The next step is, so to say, the icing on the cake. The racquet will be painted,” said Schwenger. All that’s left to do is to add the strings of your choice and you’re ready to play.

How to customize your racquet

When a HEAD racquet leaves the factory and ends up in your hands, that doesn’t have to be the end of the process for creating the perfect frame for you. Many players, including professionals, like to customize their racquet so that it plays exactly as they want. There are many ways of tweaking a racquet, which alters the weight and balance and changes how it performs.

Depending on what you’re looking for, you can boost the power, expand the sweetspot, enhance the stability and increase the swing-weight. Or you might wish to increase the weight of your racquet without changing the balance point or make your racquet more head-light. Click here for more tips here on how to create your bespoke tennis racquet.

Creating the best racquet for you

Now you know how much care and craftsmanship go into creating each HEAD frame. “Just like with food, there are many different tastes in tennis if we talk about racquets. Some like a crisp frame, some like a plush frame. Some like a lively frame, some like a more dampened frame,” said Schwenger. “And this is why it’s very important that we try to make the best racquet for you out there, the customer.”